|

I

believe Cerakote™

is the best gun coating on the market and this page will

explain why.

For additional information please vsit the Cerakote

Firearms Coatings Website.

Cerakote

Corrosion Resistance

Salt

Spray (ASTM B117) Corrosion testing is used to evaluate the relative

corrosion resistance of coated panels exposed to a salt spray or

fog at an elevated temperature. Coated panels are placed in an enclosed

salt spray chamber at a 15-30 degree angle and subjected to a continuous

indirect spray of a neutral (ph 6.5-7.2) salt water solution. The

chamber/cabinet is kept at an operating temperature of 95F and fogging

a 5% salt solution at the required 12mllhr. Cerakote™ H-146

Graphite Black panels were checked for corrosion at specific intervals

of 45, 160, 255, 385, 675, 850, 1000, 2000, 3000 and 3500 hours.

At 3500 hours Cerakote™ H-146 was not corroded. This study

shows that Cerakote™ preserves the life of a firearm in a

corrosive environment longer than any competitive coatings.

Cerakote

Abrasion Resistance

Taber

Abrasion is a test using a weighted abrasive wheel that rotates

at a constant speed to determine the resistance of finishes to abrasion

and wear, as stated by test standard ASTM D4060. 7 competitive finishes

including Cerakote™ H-146 Graphite Black were tested in accordance

with ASTM D4060. Each finish was tested three separate times in

order to validate the test result. Panel weights and mil thickness

were measured prior to the start of each test to determine a wear

rating. A 1000 gram weight was placed on a CS-17 Taber Abrasion

wheels as required by ASTM testing standards for testing finishes.

Panels were cycled until the Taber wheel wore through the finish

to the steel substrate. Finishes that required more than 500 cycles

to wear through to the substrate were stopped every 500 cycles for

the Taber abrasion wheels to be cleaned. Cleaning the Taber wheels

every 500 cycles is a requirement to ensure accurate results. Once

the Taber wheel has breached the finish, the Taber abrader is stopped

and a final weight is taken to determine the wear rating for each

finish. Wear ratings are calculated by taking the weight of the

test panel before abrasion and subtracting the weight of the test

panel after abrasion and multiplying that by 1,000. That number

is then divided by the number of cycles completed before the finish

was worn through. The resulting number is the specified wear rating

for that finish. Based on ASTM testing standard D4060, Cerakote™

Finished Strong by lasting nearly twice as long as the nearest competitive

finish and 24 times as long as the furthest competitive finish.

Cerakote

Durability Resistance

Impact

Resistance (ASTM D2794) measures the resistance of organic coatings

to the effects of rapid deformation (impact). Impact resistance

is measured by placing a coated panel in a universal impact tester.

A standard weight is dropped a distance to strike an indenter that

deforms the coatings and the substrate. The indentation can be either

an intrusion or an extrusion. By gradually increasing the distance

the weight drops. (1 inch at a time) the point at which failure

occurs can be determined by cracking or delimitation of the coating.

Cerakote™ H-146 Graphite Black was tested to have an impact

strength measuring 160 inch-lbs which is the maximum the impact

tester, can measure.

Cerakote

Hardness Resistance

Hardness,

or Pencil Hardness (ASTM D3363), is measured by using different

grades of pencil lead to cut through a coating surface. To conduct

this test, a coated panel is placed on a flat, horizontal surface.

A weighted trolley with the hardest pencil lead (9h) is placed on

the panel and pushed away from the operator. The length of the stroke

should be about 6.5 mm. This process is repeated until a lead is

found that will not cut through the coating to the metal for a distance

of at least 3 mm (this is the pencil hardness rating). This process

is then repeated until a lead is found that will not cut nor scratch

the coating (this is the scratch hardness rating). Cerakote™

H-146 Graphite Black finished strong with a 9h hardness rating,

the highest hardness rating that can be achieved.

Cerakote

Flexibility Resistance

Flexibility,

or Mandrel Bend (ASTM D522), testing is measured by placing a coated

panel in a conical Mandrel apparatus and bending the coated test

panel over a conical shaped mandrel in order to assess the elastically

or resistance of a coating to cracking, elongation and/or detachment

from the metal test panel in accordance with ASTM D522. The conical

shape of the bending area allows the deformation of the test panel

and examination of the elasticity range of a coating over any diameter

between 3.1 mm and 38 mm in one single test. Cerakote™ H-146

Graphite Black was tested in accordance with ASTM D522 and exhibited

excellent flexibility and no signs of cracking, elongation or detachment

from the steel panel.

Cerakote

Chemical Resistance

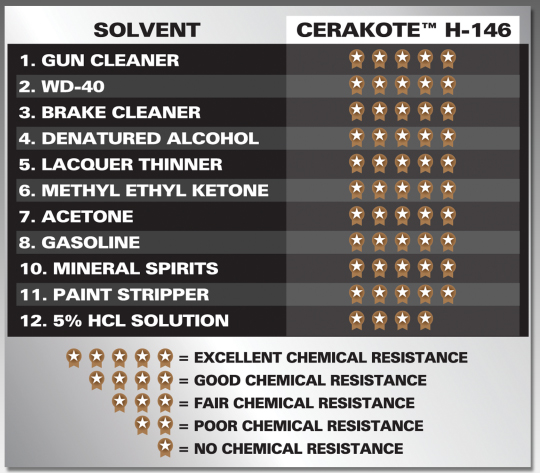

The

ability of Cerakote™ H-146 to resist chemical attack was tested

by dipping coated panels into a series of solvents to which the

coating may be exposed during regular use and extreme conditions.

The panels were placed in the solution and allowed to sit for 24

hours. Afterward, the samples were removed, analyzed and assigned

a rank depending on the resistance to each specific chemical. The

results of this test are shown in the table below. The performance

of Cerakote™ H-146 was classified as excellent for 14 of the

solvent tests. This indicates that the coating was not affected

following a 24•hour immersion in the solvents. The coating

also showed good resistance to HCI and experienced only a slight

change in texture after 24 hour immersion.

Cerakote

Adhesion Resistance

Adhesion

(ASTM 03359), is a test method to analyze whether a coating has

adhered to metal substrate. Cerakote™ H-146 was applied to

a set of steel panels and a crosshatch patter is made though the

coating to the substrate Pressure-sensitive tape is applied over

the crosshatch cut and then the tape is smoothed into place over

the area of the incisions. The tape is then removed by pulling it

off rapidly back over itself as close to an angle of 1800 and the

adhesion of the coating to the steel is assessed on a 08 to 58 scale

(shown). Cerakote™ H-146 Finished Strong with a 58 adhesion

rating, the highest adhesion rating possible.

So now you know why I believe that Cerakote™ is the best choice

for firearms coating. |